Digital Transformation Through 5G Standalone (SA)

A key current focus for Nokia and Rockwell Automation is the use of licensed, or lightly licensed, spectrum as an enabler for private cellular performance and robustness. In the United States, Citizens Broadband Radio Service (CBRS) provides 150 MHz of lightly licensed spectrum for use with private LTE and 5G networks. This spectrum can be requested in 10 MHz increments and used at no cost. Additionally, guaranteed access to up to 20 MHz of spectrum can be purchased via Priority Access Licenses (PALs). Private 5G is validated and ready for industrial use today, with an increasing number of customers showing trust in 5G. Consequently, the adoption of 5G standalone (SA) and CBRS is a hotter topic than ever.

Nokia and Rockwell Automation have teamed up to evaluate private 5G SA networks using CBRS spectrum for real-time industrial control with EtherNet/IP™ protocols. This technology partnership enhances industrial connectivity, leveraging Nokia's robust 4G LTE and 5G technologies to optimize manufacturing operations with high-speed and reliable connectivity. Since EtherNet/IP™ is transported over TCP/IP, multiple automation devices can be supported behind a single wireless router, without any of the special tunneling or extra equipment that is currently required for other industrial Ethernet protocols.

By integrating industrial automation expertise from Rockwell Automation with wireless technology expertise from Nokia, the collaboration improves operational efficiency through greater automation, real-time data collection and analytics. This synergy streamlines processes, reduces downtime and increases overall efficiency. Additionally, the technology partnership helps ensure a secure and dedicated network infrastructure, crucial for industrial applications.

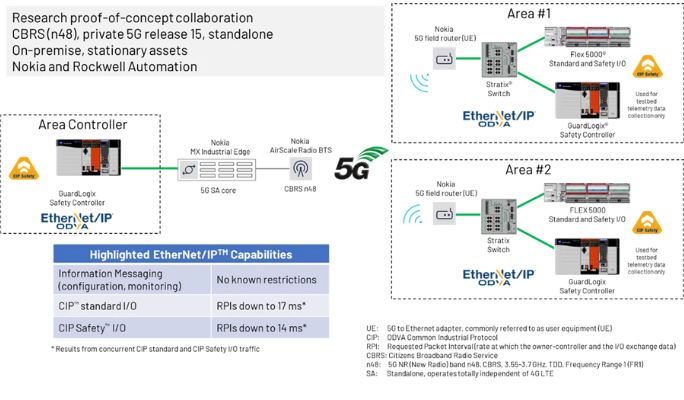

The above illustration is a simplified representation of the test bed that was used for the collaborative testing. It represents an untethered stationary industrial asset application use case, consisting of:

- One area controller with a GuardLogix® safety controller

- Two distributed areas with FLEX 5000® standard and safety I/O, representing skids, machines or equipment

(Note: the purpose of the safety controller in each distributed area was to collect test bed telemetry data only).

A Nokia private solution was used, comprised of:

- 5G radio access network (RAN), 3GPP Release 15, 5G SA and operating in n48 spectrum band (CBRS). Nokia AirScale baseband unit (BBU), two AZQC AirScale radio units (RUs).

- 5G core (5GC) operating in DAC on-premise Mission-Critical Industrial Edge (MXIE) server

- Two FRRO501c industrial 5G SA routers (in cellular parlance, user equipment or UEs)

Tests were run according to a well-established test plan provided by Rockwell Automation with strict success criteria of zero connection faults over a limited 3-hour test period. The test plan included a series of test cases to establish reliable EtherNet/IP standard and safety (CIP Safety™) I/O connections from the GuardLogix® area controller on the left, with various requested packet interval (RPI) settings, over the 5G core and RAN to the FLEX 5000 standard and safety I/O in areas 1 and 2 on the right. The RPI is the period at which the controller and the distributed I/O modules exchange data.

The test successfully demonstrated that the current state of industrial 5G (3GPP release-15, SA, on-premise, CBRS spectrum) has low enough latency and jitter to support RPI settings better than Rockwell Automation’s default settings for EtherNet/IP standard and safety I/O connections. These RPI settings will support many untethered stationary industrial asset applications (skids, machines or equipment) that use EtherNet/IP standard and safety I/O communications. Importantly, aside from typical IP address assignment and network setup, no special tuning or configuration was needed on the Nokia equipment; everything worked “out of the box.”

Using the CBRS spectrum helps ensure interference-free operation for critical automation equipment, maintaining uninterrupted performance. A private network with on-site hardware keeps data on premises, minimizing latency and enhancing privacy and security. Additionally, private cellular uses SIM cards, simplifying device management on your network.

Standalone (SA) 5G networks operate without a legacy LTE network, reducing costs and complexity while providing faster connections. As a result, using 5G for all network traffic (control plus user data) greatly reduces initial connection and handover times. For use cases requiring both 5G and LTE, LTE can be integrated with 5G SA networks.

Key use cases for private 5G SA include:

- Edge-to-cloud connectivity: 5G’s low-latency, high-speed connectivity enables real-time data transmission and reliable coverage for AI and ML applications.

- Connected worker applications: 5G’s excellent coverage and bandwidth enhance mobile tools like analytics, digital twins, and AR.

- Mobile asset applications: 5G SA’s fast handover times and low latency improve connectivity for Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs).

- Untethered stationary industrial assets: 5G reduces the need for wired communications, increasing agility and reducing retooling time for industrial operations.

Outside the US, industrial private wireless networks often use licensed spectrum. The performance observed with CBRS is consistent with results using other licensed sub-6 GHz bands as used in other countries, making these findings globally applicable.

Talk to an SMC Specialist about network solutions!

Article Source: Rockwell Automation