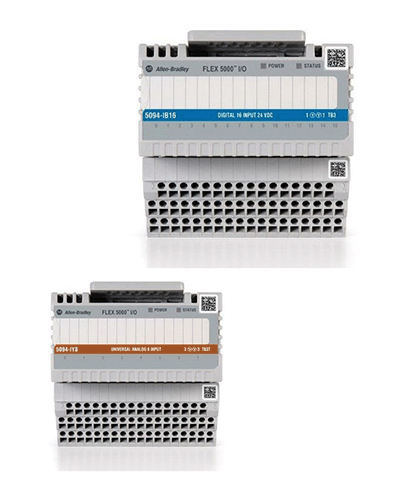

These FLEX 5000™ I/O modules are a rugged and flexible distributed I/O solution, which allows you to choose your I/O to meet your operational needs. FLEX 5000 I/O enhances communication with 1 Gb EtherNet/IP™ connectivity, which offers higher speed and increased bandwidth. To provide flexibility in your network architecture, these modules includes 2 copper or 2 fiber ports (SFP) and support for DLR, Star, Linear, and PRP topologies.

What's New?

Meet fail-safe requirements with the new FLEX 5000 analog safety I/O modules

Gain greater productivity and increased protection in a wider range of applications with our FLEX 5000 portfolio of discrete and analog fail-safe I/O modules. The new analog safety additions help meet more fail-safe requirements and minimize related downtime risks, where speed/frequency measurement, temperature sensors, pressure and flow sensor monitoring are required for functional safety protection.

- Offers integrated safety with systematic capability up to SC 3 (SIL 2 and SIL 3), TÜV certified up to SIL 3, PLe, Cat. 4, with up to 10 ms safety reaction time

- Minimize downtime through easy access to additional process diagnostics via highly integrated HART in the Studio 5000 Logix Designer® application

- Reduce system costs and complexity by mounting standard and safety I/O modules In the same I/O bank

- Ideal for hybrid and Process applications such as emergency shutdown, burner management, turbine control, compressor control, oil and gas auxiliary boilers, high-pressure protection, lighting and ventilation management

Overview

- Offers true integrated safety with discrete and analog fail-safe I/O modules, TÜV certified up to SIL 3/PLe/Cat. 4

- Enhances communication with 1 Gb EtherNet/IP connectivity through copper or fiber, with SFP adapters

- Supports a wide range of network topologies: Device Level Ring, Star, Linear and Parallel Redundancy Protocol

- Optimizes footprint with horizontal or vertical installation

- Allows users to replace modules while system is in operation with easy snap-on installation via Removal and Insertion Under Power (RIUP)

- Offers flexible and modular capability to support up to 32-channel digital and 8-channel analog input/output

- Operates in -40…+70 °C (-40...+158 °F) temperatures and in hazardous areas in Class I, Division 2, Zone 2, Groups A, B, C, D

- Allows for use in extreme environments with XT version up to G3 with conformal coating, which helps protect against environmental stresses

- Functions as remote I/O modules with ControlLogix® 5580, CompactLogix™ 5380 and CompactLogix 5480 standard controllers and with GuardLogix® 5580 and Compact GuardLogix 5380 safety controllers

- Supports ControlLogix® 5580 controller redundancy for high availability applications from Studio 5000 Logix Designer application, version 33 or later

- Allows access to highly integrated HART devices available in the I/O tree

- Provides easy access to device health via the enhanced diagnostics

- Reduces engineering through tight integration with PlantPAx 5.0and above instruction set

- Simplifies maintenance with visibility to device tag diagnostics based on Device Description (DD) files

- Reduces downtime by adding and replacing Process devices online

- Increases productivity with easier device configuration of process devices via embedded device type managers (DTM)

Choose this reliable and flexible I/O solution, which allows you to choose your I/O to meet your operational needs. Shop now to begin integrating FLEX 5000™ I/O modules in your facilities.