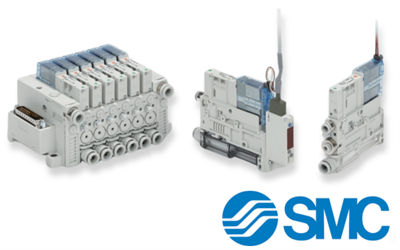

Vacuum Generators create industrial vacuum at the application's point of use utilizing the venturi effect and fluid flow from compressed air or gases. They are compact and light weight units designed for end-of-arm tooling (EOAT) on robotic arms or end effectors generating suction gripping force at the point of use while minimizing inertia. Vacuum levels as low as -27 inHG (-93 kPA) can be attained with multi-stage generators with suction flow greater than 7 SCFM (200 L/min). They can be configured into manifolds or mounted as individual units with options including: energy savings, compact, multi-stage, point-of-use, high speed release and integrated generator with suction cups.

The ZK2*A series is an energy-saving generator with 93% reduced air consumption. It has a 50% increase in suction flow compared to other single stage SMC generators. The ZK2*A also has various mounting options to choose from.

Features

- Supply valve: An N.O. specification has been added.

Can hold vacuum∗ even when the power goes out or is turned off

Prevents the sudden dropping of workpieces∗

∗ Supposing the supply pressure is being maintained

- An IO-Link compatible pressure switch has been added.

Allows for ejector control with a single communication line

Reading of the device information and parameter batch settings are

possible.

- Compatible with ejector systems and vacuum pump systems

- Energy saving ejector

Air supply is cut-off when vacuum is reached.

Air consumption: 93% reduction (Under SMC’s measurement conditions)

- More efficient ejector: Suction flow increased by 50% (Compared to other

SMC 1-stage ejectors)

- Energy saving efficiency: 93% reduction

- Improved low noise and suction flow by adoption of a high-noise

reduction silencer

SMC USA ZK2*A products available below!